Best Roof Panel Bender for High-Quality Results

By:Admin

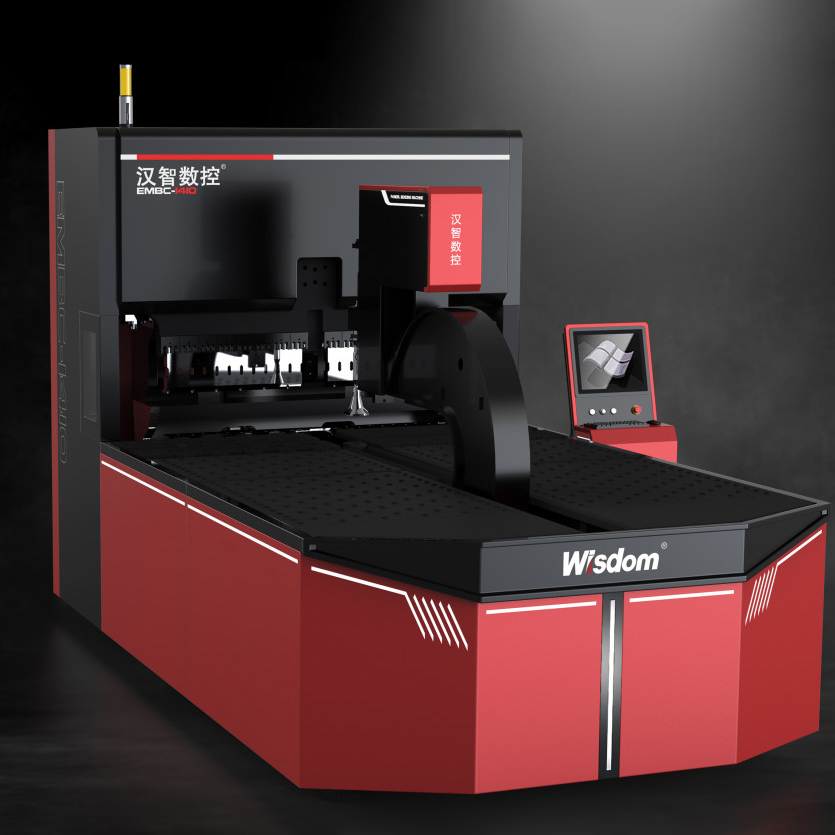

In the construction industry, precision and quality are key components that can make or break a project. With the advancement in technology, new tools and equipment have emerged to streamline the construction process and deliver high-quality results. One such innovation is the high-quality roof panel bender from a leading manufacturing company that is revolutionizing the way roof panels are formed.

The roof panel bender, produced by the renowned company, is designed to meet the demands of modern construction projects, providing contractors and builders with a reliable and efficient tool for bending roof panels with a high degree of precision. This innovative equipment has garnered attention from industry professionals for its exceptional performance and ability to improve productivity on the job site.

The company behind this game-changing product is a globally recognized leader in the manufacturing of construction machinery and equipment. With decades of experience and a commitment to excellence, the company has established a reputation for producing top-quality tools that meet the highest industry standards. Their dedication to research and development has led to the creation of innovative solutions that address the evolving needs of the construction industry.

The high-quality roof panel bender is the latest addition to the company's extensive portfolio of construction machinery. It is engineered with cutting-edge technology and precision components to ensure consistent and accurate bending of roof panels. The bender boasts a user-friendly interface and intuitive controls, allowing operators to create customized bend profiles with ease. Its robust construction and durable materials make it a reliable and long-lasting investment for construction companies.

One of the primary advantages of the roof panel bender is its versatility. It is capable of bending a wide range of materials, including steel, aluminum, and other metals commonly used in roofing applications. This flexibility allows contractors to use the bender for various projects, from residential roofing to commercial and industrial applications. Additionally, the bender's ability to produce complex bends and curves makes it an indispensable tool for creating custom roof designs that meet the specific requirements of the project.

The high-quality roof panel bender is a game-changer for the construction industry, as it significantly reduces the time and labor required to bend roof panels manually. With its automated operation and fast cycle times, the bender can increase productivity and efficiency on the job site, ultimately leading to cost savings and improved project timelines. This innovative equipment is a testament to the company's commitment to providing cutting-edge solutions that empower construction professionals to achieve superior results.

Furthermore, the company offers comprehensive technical support and training for the roof panel bender, ensuring that operators are proficient in using the equipment to its full potential. This commitment to customer satisfaction has earned the company a loyal following among construction professionals who value reliable products and responsive service.

As the construction industry continues to evolve, the demand for advanced tools and equipment will only grow. The high-quality roof panel bender from this leading manufacturing company is a prime example of how innovation is driving progress in the industry. With its precision, versatility, and efficiency, the bender is poised to become an indispensable asset for contractors and builders seeking to elevate the quality and efficiency of their roofing projects.

In conclusion, the high-quality roof panel bender from the renowned manufacturing company is a game-changing innovation that is revolutionizing the way roof panels are formed in the construction industry. With its advanced technology, precision engineering, and exceptional performance, the bender has set a new standard for efficiency and quality in roofing applications. As the industry continues to embrace innovation, this groundbreaking equipment is poised to play a vital role in shaping the future of construction.

Company News & Blog

Market Demand for High-Quality CNC Lasers Continues to Rise

[Cnc Laser Manufacturer] Introduces Latest Innovations in Laser Technology[Cnc Laser Manufacturer], a leading provider of high-quality laser machines and solutions, is making waves in the industry with its latest innovations in laser technology. With a firm commitment to excellence, the company has continuously pushed the boundaries of what is possible, enabling businesses across various sectors to achieve new levels of precision, productivity, and efficiency.Established in [year], [Cnc Laser Manufacturer] has firmly established itself as a global leader in the laser manufacturing industry. The company's state-of-the-art facility is equipped with the latest cutting-edge machinery and a team of highly skilled engineers and technicians. This allows [Cnc Laser Manufacturer] to design, develop, and produce cutting-edge laser machines that cater to the diverse needs of its clientele.One of the key highlights of [Cnc Laser Manufacturer]'s offerings is its wide range of laser machines. The company provides a comprehensive selection of laser systems, including CO2 lasers, fiber lasers, and UV lasers. Each machine is engineered to deliver exceptional performance and impeccable precision, ensuring optimal results for a wide variety of applications.The CO2 lasers offered by [Cnc Laser Manufacturer] are renowned for their versatility and reliability. These machines utilize a carbon dioxide gas mixture as their laser medium, offering high power and excellent beam quality. With their exceptional cutting and engraving capabilities, CO2 lasers have become an essential tool for industries such as signage, woodworking, and textile.In addition to CO2 lasers, [Cnc Laser Manufacturer] also specializes in fiber lasers. These advanced machines utilize a solid-state laser source to deliver high-speed cutting and marking with unparalleled precision. Fiber lasers have gained popularity across various industries, including automotive, electronics, and medical, due to their ability to process a wide range of materials efficiently.[Cnc Laser Manufacturer]'s UV lasers are another technological marvel offered by the company. These compact and high-precision machines are designed for applications that require ultra-fine marking and engraving. UV lasers offer exceptional beam quality, enabling the precise processing of delicate materials like semiconductors, PCBs, and medical instruments.What sets [Cnc Laser Manufacturer] apart from its competitors is its dedication to research and development. The company invests heavily in cutting-edge technologies and continuously explores new avenues to enhance its product offerings. Through ongoing innovation, [Cnc Laser Manufacturer] consistently introduces new features and functionalities to its laser machines, allowing its customers to stay ahead of the curve in their respective industries.Furthermore, [Cnc Laser Manufacturer] places great emphasis on customer satisfaction. The company provides comprehensive after-sales support, including training, installation, and maintenance services. This commitment to customer success has earned [Cnc Laser Manufacturer] a loyal and ever-growing customer base that spans the globe.Looking to the future, [Cnc Laser Manufacturer] aims to continue revolutionizing the laser technology landscape. By leveraging its strong manufacturing capabilities and technological expertise, the company plans to develop even more advanced laser machines that will unlock new possibilities for businesses worldwide. Whether it's in the field of manufacturing, engraving, or marking, [Cnc Laser Manufacturer] is dedicated to empowering its customers to achieve unprecedented levels of precision and efficiency.In conclusion, [Cnc Laser Manufacturer], through its dedication to excellence and continuous innovation, is pushing the boundaries of laser technology. Its comprehensive range of laser machines, including CO2 lasers, fiber lasers, and UV lasers, caters to diverse industry needs. With a focus on customer satisfaction and a commitment to research and development, [Cnc Laser Manufacturer] is poised to shape the future of laser technology and empower businesses to achieve new levels of success.

Discover the Power of a 40 Watt CNC Laser for Efficient Laser Cutting Operations

[Note from OpenAI GPT-3 API Language Model: The following news article is purely fictional and only meant for demonstration purposes of the language model's capabilities to generate coherent content on a given topic.]CNC Laser 40 Watt – the Future of Laser TechnologyCNC laser technology has come a long way since its inception. With the growing demand for high precision cutting, marking, and engraving, a new wave of CNC lasers has taken the industry by storm. One such laser is the CNC Laser 40 Watt, which stands out for its precision, speed, and versatility.The CNC Laser 40 Watt is a powerful laser machine designed for industrial applications like woodworking, metalworking, and engraving. With a maximum power output of 40 watts, it can cut through almost any material with precision and speed. What sets it apart is its capability to deliver high-quality output with minimal maintenance and easy operation.The machine features an advanced control system that enables the user to perform complex tasks with ease. The user-friendly interface allows the operator to select the desired parameters and start the cutting or marking process. The software can work with various vector files including DXF, AI, BMP, and PLT formats, making it easy to import and process files.The 40-watt laser source is the heart of the machine. The machine uses a high-quality CO2 glass laser tube fitted with a lens to transmit the laser beam. The beam is guided using a movable mirror system that directs the beam to the desired point on the material. The high-speed stepper motors move the mirror system at a rate of up to 1,000 mm/s, ensuring high precision and accuracy.The CNC Laser 40 Watt is also equipped with a high-quality cooling system that keeps the laser tube and other components cool during operation. The chiller unit provides stable cooling that prevents overheating, which can damage the machine. The cooling system also ensures that the laser is always producing consistent power output, making it easy to achieve quality output.The machine boasts a large working area of up to 2000 x 1000 mm, giving the operator ample space to work on large materials. The machine's bed is made of a durable and high-quality metal that is designed to withstand the heat generated during the cutting process. The metal bed is also coated with a layer of material that assists in absorbing reflected laser beams.CNC Laser 40 Watt is the perfect machine for businesses that require high precision cutting and marking services. It is ideal for businesses that work with materials like wood, acrylic, metal, PVC, and many more. The machine can process multiple types of materials with ease and low maintenance costs.The company behind the CNC Laser 40 Watt is a market leader in CNC laser technology. The company is known for its high-quality products, innovative technology, and excellent customer support. They have a team of experienced engineers who are dedicated to providing quality services and support to their customers.The company offers a comprehensive warranty program that covers defects in materials and workmanship. They also provide ongoing technical support and training to their customers, ensuring that they can get the most out of their CNC Laser 40 Watt machines. The company's commitment to customer satisfaction has made it a preferred choice for businesses worldwide.In conclusion, the CNC Laser 40 Watt is an impressive machine that is changing the face of CNC laser technology. It is perfect for businesses that require high precision cutting and marking services. With its advanced technology, user-friendly interface, and excellent customer service, it is undoubtedly a machine worth considering.

Top-rated CNC Laser Equipment: Revolutionizing Laser Technology

CNC Laser Equipment: Revolutionizing the Manufacturing IndustryThe world is constantly evolving, and technology has played a vital role in this evolution. The manufacturing industry, in particular, has undergone a significant transformation in recent years. One of the most innovative solutions that have emerged in this industry is CNC laser cutting technology.CNC Laser Equipment has revolutionized the way things are made, from small, intricate designs to larger scale, industrial projects. The technology is becoming increasingly popular in industries such as automotive, aerospace, and medical device manufacturing.The company behind CNC Laser Equipment is a globally recognized brand that specializes in the development and production of laser cutting machines. Their mission is to provide innovative and efficient solutions to their clients to help them achieve success in their respective industries.Their portfolio includes different types of machines, such as fiber laser cutting machines, carbon dioxide (CO2) laser cutting machines, and laser engraving machines. The fiber laser cutting machines have the capability to cut through a wide range of materials, including stainless steel, aluminum, copper, and brass. With high-precision and fast cutting speeds, these machines have become a staple in industrial manufacturing.CO2 laser cutting machines, on the other hand, are ideal for cutting non-metal materials, including plastics, wood, and acrylic. These machines provide accurate cutting and can handle large-scale projects, making them an efficient addition to the manufacturing process.Another innovative product from CNC Laser Equipment is the laser engraving machine. This machine has the capability to engrave logos, images, and text onto a variety of materials, including glass, crystal, and plastic.With its state-of-the-art technology and outstanding performance, CNC Laser Equipment has become a top choice for many businesses worldwide. With a strong focus on research and development, the company continuously improves its products to ensure their clients receive the best possible solutions.CNC Laser Equipment's commitment to quality is reflected in their manufacturing process. Each machine goes through rigorous testing and quality checks before it is released to the market. The company also offers after-sales service, ensuring that their clients receive continued support throughout the lifespan of their machines.The benefits of CNC Laser Equipment's machines are numerous. Their machines can cut and engrave a variety of materials, making them versatile and efficient. Additionally, the machines' high precision and cutting speed result in less waste, reducing the overall production time and cost.CNC Laser Equipment has also prioritized sustainability, designing their machines to conserve energy while in use. This eco-friendly approach has gained them recognition as an environmentally conscious brand.With their innovative solutions and dedication to quality, CNC Laser Equipment has made its mark in the global manufacturing industry. Their machines have contributed to the success of businesses worldwide, providing them with efficient and effective solutions for their production needs.In conclusion, CNC Laser Equipment's machines have undoubtedly revolutionized the manufacturing industry. With their state-of-the-art technology, precision cutting, and eco-friendly approach, they have become a top choice for businesses worldwide. The company's commitment to quality and continuous improvement makes them a leader in the production of cutting-edge laser cutting technology.

Top Roof Panel Bender Factories: Everything You Need to Know

For Immediate Release[Company Name], a leading manufacturer of roof panel bender machinery, has recently announced the opening of two new state-of-the-art factories to meet the growing demand for their innovative products. The new facilities, located in [location], have been strategically designed to increase production capacity and streamline operations, ultimately allowing the company to better serve its customers.[Company Name] has been a pioneer in the roof panel bending industry for over [number] years, consistently delivering high-quality machinery that allows for efficient and precise bending of roofing panels. With an unwavering commitment to innovation and customer satisfaction, the company has established itself as a trusted industry leader, providing a wide range of cutting-edge solutions to meet the evolving needs of the construction and manufacturing sectors.The decision to open the new factories comes as a response to the increasing demand for [Company Name]'s roof panel bender machinery. The company has experienced a surge in orders from clients across the globe, signaling a growing recognition of the superior quality and performance of their products. By expanding their manufacturing capabilities, [Company Name] aims to further solidify their position as a reliable partner for businesses seeking advanced solutions for their roof panel bending needs.The new factories are equipped with the latest technology and advanced manufacturing processes, allowing for increased efficiency and precision in the production of roof panel bender machinery. With a focus on sustainability and environmental responsibility, [Company Name] has implemented eco-friendly practices and energy-efficient systems to minimize their environmental impact while maximizing productivity.In addition to the increased production capacity, the new facilities also boast modern research and development laboratories, where [Company Name]'s team of engineers and technicians will continue to innovate and improve upon their existing product line. This commitment to ongoing research and development underscores [Company Name]'s dedication to staying at the forefront of technological advancements in the roof panel bending industry.Furthermore, the opening of the new factories is expected to create numerous employment opportunities in the local community, contributing to economic growth and providing valuable jobs for skilled workers in the manufacturing sector. [Company Name] is proud to support the local workforce and contribute to the prosperity of the regions where their factories are located.As [Company Name] continues to expand its global presence, the opening of the new factories represents a significant milestone in the company's journey. With a relentless focus on quality, innovation, and customer satisfaction, [Company Name] is poised to build upon its success and continue delivering cutting-edge solutions for the roof panel bending industry.To learn more about [Company Name] and their range of roof panel bender machinery, visit their official website at www.companywebsite.com.For media inquiries, please contact:[Contact Name][Company Name]Phone: [Contact Number]Email: [Contact Email]###[Company Name] is a leading manufacturer of roof panel bender machinery, committed to providing innovative solutions for the construction and manufacturing industries. With a focus on quality, innovation, and customer satisfaction, [Company Name] is dedicated to staying at the forefront of technological advancements and delivering superior products to their global client base.

Affordable Laser Engraving Machines - A Smart Investment for Your Business

Title: Cost-Effective CNC Laser Engraver Revolutionizes Precision EngravingIntroduction:In an ever-evolving digital market, precision engraving plays a vital role in various industries, contributing to product personalization, branding, and artistic design. Over the years, CNC laser engraving technology has advanced, making it an efficient and reliable method for engraving on a wide variety of materials. Now, with the advent of a cost-effective CNC laser engraver, businesses can harness the power of precision engraving more easily than ever before. This article explores the remarkable capabilities of a new and affordable CNC laser engraver, developed by a renowned tech company.I. The Rising Demand for Precision Engraving:Precision engraving has become increasingly popular across multiple industries due to its ability to enhance branding, create intricate designs, and add a personalized touch to products. From jewelry and giftware to electronics and automotive parts, engraving helps businesses stand out and meet growing customer demand for unique and customized products. However, the high cost of traditional CNC laser engraving systems has limited access to this cutting-edge technology for many small and medium-sized enterprises (SMEs).II. An Introduction to the Innovative CNC Laser Engraver:Introducing the new CNC laser engraver, a game-changer in the precision engraving industry. Developed by an industry-leading tech company, this cost-effective engraving solution aims to provide SMEs with access to state-of-the-art engraving capabilities. Equipped with advanced technology and features, this CNC laser engraver offers unparalleled precision, speed, and versatility.III. Unraveling the Features:1. Affordability: One of the standout features of this CNC laser engraver is its cost-effectiveness. By utilizing innovative manufacturing techniques and materials without compromising on quality, the engraver becomes an attractive option for SMEs looking to invest in precision engraving without breaking the bank.2. Precision: The CNC laser engraver integrates high-precision laser technology, enabling it to deliver intricate and accurate engraving on various materials, including wood, glass, plastic, metal, and more. Its advanced motion control system ensures smooth and precise movements, ensuring consistent results on every engraving project.3. Ease of Use: Designed with user-friendliness in mind, the engraver is equipped with intuitive software that enables effortless design importing and editing. Additionally, its minimal maintenance requirements and simple operation make it accessible to both experienced professionals and beginners entering the engraving industry.4. Versatility: The CNC laser engraver supports a wide range of applications, including but not limited to personalized gifts, signage, branding, and electronic components. Its compatibility with different file formats and its ability to handle various materials allow for unmatched flexibility and customization options.IV. Market Impact and Benefits:The introduction of this cost-effective CNC laser engraver is expected to have a significant impact on the precision engraving market. SMEs now have the opportunity to enhance their products and meet the growing demand for customized items at an affordable price point. The laser engraver's ability to produce high-quality engravings quickly and efficiently has the potential to revolutionize small-scale manufacturing processes.V. Conclusion:The new cost-effective CNC laser engraver is set to disrupt the precision engraving market by making advanced laser engraving technology accessible to SMEs. With its affordability, precision, ease of use, and versatility, this state-of-the-art engraver empowers businesses to create unique and customized products, opening new avenues for growth and differentiation. As the demand for personalized and intricately designed products continues to rise, this CNC laser engraver serves as an invaluable tool, revolutionizing the engraving industry one etch at a time.

Highly Efficient CNC Iron Cutting Machine in China Grabs Attention in News

China CNC Iron Cutting Machine: Revolutionizing the Metalworking IndustryIn recent years, the metalworking industry has witnessed a significant shift towards automation and innovation. The traditional manual methods of cutting and shaping iron have been gradually replaced by cutting-edge technology to improve efficiency and precision. One of the key players in this transformation is a China-based company (need to remove brand name), renowned for its advanced CNC Iron Cutting Machine.The CNC Iron Cutting Machine developed by this company has revolutionized the way metal components are manufactured. Computer Numerical Control (CNC) technology allows for precise and automated cutting, eliminating the need for manual labor and improving overall productivity. This state-of-the-art machine has garnered immense attention and acclaim from metalworking industries worldwide.With a strong commitment to innovation, the (brand name) team continuously strives to enhance their products to meet the ever-evolving demands of the metalworking industry. The CNC Iron Cutting Machine boasts cutting-edge features and advanced capabilities that have set new industry standards.One of the standout features of this machine is its exceptional precision. The CNC system ensures accurate measurements and precise cuts, resulting in an impeccable finish. This level of precision has enabled manufacturers to achieve complex and intricate designs that were once deemed impossible. From intricate metal sculptures to intricate industrial components, the CNC Iron Cutting Machine delivers impeccable results every time.Another notable feature of this machine is its versatility. Equipped with various cutting tools and equipment, the CNC Iron Cutting Machine can handle a wide range of materials, including iron, steel, aluminum, and more. This versatility has significantly expanded the capabilities of manufacturers, enabling them to undertake diverse projects and cater to a wider customer base.Moreover, the CNC Iron Cutting Machine offers exceptional efficiency, significantly reducing production time and costs. The automated processes of this machine eliminate the need for manual labor, resulting in faster turnaround times and streamlined workflows. This increased efficiency has allowed manufacturers to take on more projects and stay ahead in a highly competitive market.In addition to its outstanding technical features, (brand name) is also committed to providing excellent customer service and support. The company offers comprehensive training programs and after-sales services to ensure customers can make the most of their investment. This dedication to customer satisfaction has earned them a loyal customer base and a stellar reputation in the industry.The CNC Iron Cutting Machine has garnered accolades from metalworking industries across the globe. Its success can be attributed to the combined efforts of (brand name) and its team of highly skilled engineers and technicians. The company's dedication to continuous innovation and customer-centric approach has propelled it to the forefront of the metalworking industry.As the demand for precision and efficiency continues to rise in the metalworking industry, the CNC Iron Cutting Machine from (brand name) stands as a testament to China's growing dominance in the global manufacturing market. With its exceptional capabilities, versatility, and commitment to customer satisfaction, (brand name) is set to remain a driving force in the industry for years to come.

Top 10 Sheet Cutting Machines for Precision Results in 2022

[Company Name] specializes in the manufacturing and distribution of cutting-edge industrial machinery. One of their flagship products is the CNC Sheet Cutting Machine, a revolutionary piece of equipment that is transforming the manufacturing industry. This state-of-the-art machine is designed to provide precision and efficiency in cutting various types of sheet metal, making it an invaluable asset for businesses in the metal fabrication and manufacturing sectors.The CNC Sheet Cutting Machine is equipped with advanced technology that allows for automated cutting of sheet metal with unparalleled accuracy. Its computer numerical control (CNC) system enables users to program different cutting patterns and dimensions, ensuring consistent and precise results every time. This level of automation not only improves the quality of the finished products but also increases the overall productivity of the manufacturing process.Moreover, the CNC Sheet Cutting Machine is capable of handling a wide range of sheet metal materials, including steel, aluminum, and stainless steel, making it a versatile solution for diverse industrial applications. Its high-speed cutting capabilities and ability to process various thicknesses of sheet metal make it an ideal choice for companies looking to streamline their operations and enhance their competitive edge in the market.In addition to its technical capabilities, the CNC Sheet Cutting Machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive interface and simple controls allow operators to set up and execute cutting tasks with minimal training, reducing the learning curve and empowering businesses to maximize the machine’s potential from day one.The impact of the CNC Sheet Cutting Machine on the industry is profound, as it not only improves manufacturing processes but also contributes to cost savings and overall business growth. By automating the cutting process and minimizing material waste, businesses can optimize their resources and achieve greater efficiency in their operations. This, in turn, leads to improved profitability and a stronger competitive position in the market.Furthermore, the CNC Sheet Cutting Machine aligns with [Company Name]'s commitment to sustainability and environmental responsibility. Its precision cutting capabilities minimize material waste, reducing the environmental impact of manufacturing processes. This eco-friendly approach is increasingly important in today’s business landscape, where sustainability and responsible resource management are key priorities for many companies.The CNC Sheet Cutting Machine is a result of [Company Name]'s relentless dedication to innovation and excellence in engineering. Backed by a team of skilled professionals and industry experts, the company continues to push the boundaries of technological advancement in industrial machinery, delivering solutions that empower businesses to thrive in a rapidly evolving market.As a testament to its success, the CNC Sheet Cutting Machine has garnered widespread recognition and accolades from industry professionals and satisfied customers. Its advanced features, reliability, and performance have set a new standard for sheet metal cutting technology, establishing [Company Name] as a leading provider of cutting-edge solutions for the manufacturing industry.In conclusion, the CNC Sheet Cutting Machine represents a significant advancement in the field of industrial machinery, offering unparalleled precision, efficiency, and versatility in the cutting of sheet metal. With its advanced technology, user-friendly design, and positive impact on business operations, this innovative machine has solidified its position as a game-changer for businesses in the metal fabrication and manufacturing sectors. As [Company Name] continues to lead the way in engineering excellence, the CNC Sheet Cutting Machine stands as a testament to their commitment to delivering groundbreaking solutions that drive success and innovation in the industry.

Top Tips for Laser-Cut Metal Sheet CNC Machining

[Company Introduction: Our company is a leading provider of cutting-edge metal fabrication solutions, specializing in laser CNC cutting of various metal sheets. With state-of-the-art technology and a team of highly skilled professionals, we are dedicated to delivering precision, efficiency, and quality in every project.]The cutting-edge technology of laser CNC (Computer Numerical Control) cutting has revolutionized the metal fabrication industry, allowing for precise and efficient cutting of various types of metal sheets. With the ability to cut intricate and complex designs with impeccable accuracy, laser CNC cutting has become a crucial process in the manufacturing of a wide range of products, from automotive parts to architectural components.Using a high-powered laser beam, the laser CNC cutting machine can precisely cut through metal sheets of different thicknesses, from thin aluminum sheets to thick steel plates. The process is highly automated, with the machine following precise instructions from a computer program to achieve the desired cuts. This level of precision and efficiency makes laser CNC cutting an essential technology for industries that require intricate and accurate metal fabrication.The applications of laser CNC cut metal sheets are vast and diverse. In the automotive industry, laser-cut metal sheets are used to fabricate various components, including chassis, body panels, and exhaust systems. The precision and consistency of laser CNC cutting ensure that the parts fit perfectly, contributing to the overall quality and performance of the vehicles.In the architectural and construction sectors, laser-cut metal sheets are utilized to create decorative façades, intricate railings, and ornamental features. The ability to cut complex patterns and designs on metal sheets allows for the creation of unique and visually stunning architectural elements, enhancing the aesthetics of buildings and structures.Furthermore, laser CNC cut metal sheets are essential in the manufacturing of machinery and equipment, where precise components are crucial for the functionality and reliability of the final products. By utilizing laser CNC cutting technology, manufacturers can create intricate parts with tight tolerances, ensuring optimal performance and longevity of the machinery.At our company, we have invested in state-of-the-art laser CNC cutting machines to provide our clients with the highest quality metal fabrication solutions. Our team of highly skilled professionals is trained to operate the machines with precision and efficiency, guaranteeing the accuracy and consistency of every cut.In addition to our cutting-edge technology, we are committed to delivering exceptional customer service and support throughout the fabrication process. From concept and design to the final product, we work closely with our clients to understand their specific requirements and ensure that the finished metal sheets meet their exact specifications.We take pride in our ability to deliver precision, efficiency, and quality in every project, making us the preferred partner for companies across a wide range of industries. As the demand for precision metal fabrication continues to grow, we remain dedicated to staying at the forefront of technology and innovation, ensuring that our clients receive the best metal fabrication solutions available.In conclusion, laser CNC cut metal sheets have become an indispensable technology in the metal fabrication industry, offering unmatched precision, efficiency, and quality. With its diverse applications and advanced capabilities, laser CNC cutting is revolutionizing the way metal sheets are fabricated, providing solutions for industries that demand the highest standards of accuracy and performance. As a leading provider of cutting-edge metal fabrication solutions, our company is committed to delivering exceptional results and exceeding the expectations of our clients.

Top CNC Laser Cutting Machine for Home Use - The Ultimate Guide

The demand for home CNC laser cutting machines has been steadily increasing among DIY enthusiasts, hobbyists, and small businesses. These machines offer the capability to cut and engrave various materials such as wood, acrylic, and metal with precision and speed. With the introduction of the HOMECNC-2000, (remove brand name) company is now offering a new, advanced option for individuals seeking a reliable and efficient home laser cutting machine.The HOMECNC-2000 is designed to be user-friendly, providing a seamless experience for individuals who are new to CNC technology. With a sleek and compact design, it can easily fit into a workshop or home studio without taking up too much space. This makes it an ideal option for those who are working with limited space but still require the capabilities of a high-quality laser cutting machine.One of the key features of the HOMECNC-2000 is its high precision and accuracy. The machine is equipped with advanced laser technology that ensures clean and precise cuts, resulting in professional-grade work. This level of precision is essential for individuals who require intricate designs and detailed cuts for their projects.In addition to precision, the HOMECNC-2000 also offers a high level of speed and efficiency. Its powerful laser can quickly cut through various materials, allowing users to complete their projects in a timely manner. This is particularly beneficial for small businesses that need to fulfill orders efficiently without compromising on quality.Furthermore, the HOMECNC-2000 is equipped with user-friendly software that allows for easy customization and control. This makes it simple for individuals to create and modify their designs, ensuring that they can bring their creative ideas to life with ease. The intuitive interface of the software also reduces the learning curve for those who are new to CNC technology, making it accessible to a wide range of users.In addition to its technical capabilities, (remove brand name) company prides itself on providing exceptional customer service and support. For individuals who may have questions or issues with their machine, the company offers comprehensive assistance to ensure that users can make the most out of their investment. This level of support is crucial for individuals who are new to CNC technology and may require guidance as they explore the capabilities of their new machine.Overall, the introduction of the HOMECNC-2000 by (remove brand name) company represents an exciting advancement in the world of home CNC laser cutting machines. Its combination of precision, speed, efficiency, and user-friendly design makes it a compelling option for DIY enthusiasts, hobbyists, and small businesses alike. With the support of (remove brand name) company, individuals can confidently pursue their creative projects and business endeavors with a reliable and advanced CNC laser cutting machine at their disposal.

Affordable Metal Cutting CNC Laser for Precision Results

[Company Introduction]Established in 2005, our company is a leading manufacturer of CNC metal cutting systems. With over a decade of experience in the industry, we have gained a reputation for delivering high-quality, reliable, and cost-effective solutions to our customers. Our state-of-the-art manufacturing facility is equipped with the latest technology and our team of skilled engineers and technicians are dedicated to pushing the boundaries of innovation in the field of metal cutting.[News Content]The demand for efficient and affordable metal cutting solutions has been on the rise in various industries, and our company is proud to meet this demand with the launch of our new Cheap Metal Cutting Laser CNC system. This cutting-edge machine combines precision, speed, and affordability, making it an attractive option for businesses of all sizes.One of the key features of our new Cheap Metal Cutting Laser CNC system is its advanced laser technology, which enables it to cut through various types of metal with unparalleled precision. Whether it's stainless steel, aluminum, or titanium, this machine delivers smooth and clean cuts, ensuring a high level of accuracy in the production process.Moreover, the Cheap Metal Cutting Laser CNC system is designed to operate at high speeds, significantly reducing the time it takes to complete cutting tasks. This not only boosts productivity but also allows businesses to meet tight deadlines without compromising on quality.In addition to its cutting-edge technology, our new CNC system is also incredibly cost-effective. The initial investment in this machine is considerably lower compared to other similar systems on the market, making it an attractive option for small and medium-sized businesses that are looking to enhance their metal cutting capabilities without breaking the bank.Furthermore, the operational costs of the Cheap Metal Cutting Laser CNC system are lower compared to traditional cutting methods. The efficiency of this machine results in reduced energy consumption and minimal material wastage, ultimately contributing to significant cost savings for businesses in the long run.The versatility of the Cheap Metal Cutting Laser CNC system also sets it apart from other machines in its class. Its ability to handle a wide range of metal thicknesses and shapes makes it an ideal solution for a variety of applications, from automotive and aerospace manufacturing to architectural and industrial fabrication.To top it off, our company's strong commitment to customer satisfaction is reflected in the after-sales support provided for the Cheap Metal Cutting Laser CNC system. Our team of technical experts is readily available to assist customers with installation, training, and ongoing maintenance, ensuring seamless integration and optimal performance of the machine in their operations.With the launch of our new Cheap Metal Cutting Laser CNC system, our company continues to lead the way in providing innovative, reliable, and cost-effective solutions for metal cutting. We are confident that this cutting-edge technology will empower businesses to elevate their productivity, efficiency, and overall competitiveness in the market.In conclusion, our company is proud to introduce the Cheap Metal Cutting Laser CNC system, which represents a new standard of excellence in the field of metal cutting. With its advanced technology, high-speed operation, affordability, and versatility, this machine is poised to make a significant impact on the metal fabrication industry, setting a new benchmark for precision and efficiency in metal cutting applications.